Mechanical

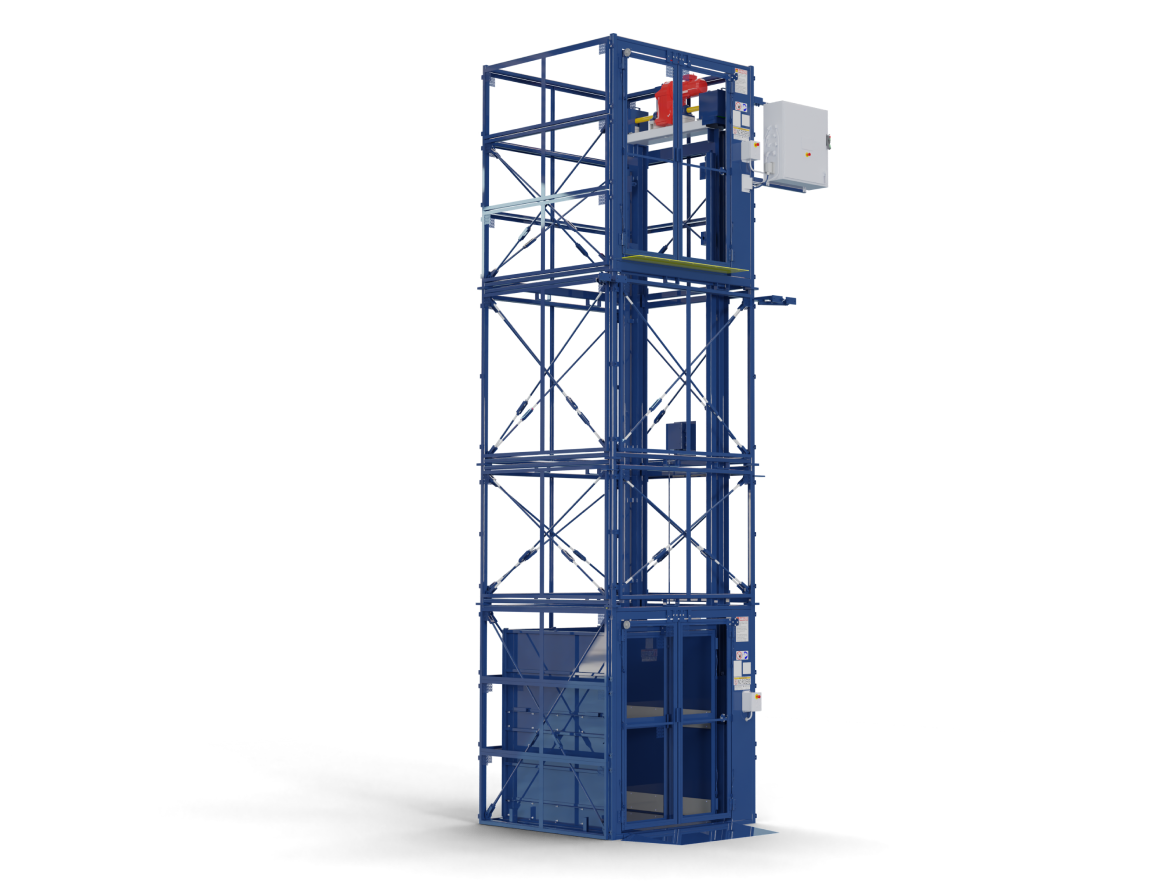

Mechanical Vertical Reciprocating Conveyor (VRC) Lifts

Understanding Mechanical VRCs in Material Handling

Mechanical Vertical Reciprocating Conveyor (VRC) lifts provide a safe, economical, and reliable solution for vertical material handling challenges.

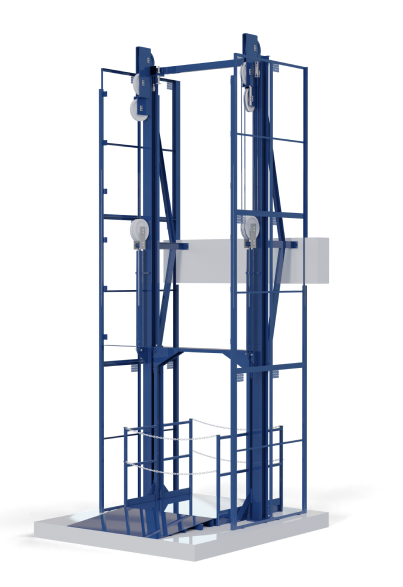

Mechanical VRCs operate with a brake motor and gear reducer with a common drive shaft. Raising and lowering the carriage platform is accomplished with a heavy-duty roller chain, providing both precision and speed.

The mechanical systems allow for a load capacity of up to 20,000 lbs., making Mechanical VRCs an ideal solution for applications with heavy loads.

Autoquip’s expert sales and design teams are here to help you find the right Mechanical VRC for your facility.

Implementing Mechanical VRCs in Your Facility

There are many advantages to having a Mechanical VRC, including the lift’s durability, cost-effectiveness, speed, and precision. The system design also allows for consistent repeatability in loading and unloading high-capacity freight.

Autoquip Mechanical VRCs come with countless customization options to ensure each requirement of your application is met, resulting in an ideal material handling solution.

With A Mechanical VRC, You Get

- High Load Carrying Capacities up to 20,000 lbs.

- Designed for multiple levels to Access Heights up to 100 ft.

- Reduced wear and maintenance for high-cycle applications

- No Risk of Hydraulic Oil Leakage in Sensitive Environments

- Better for high cycle applications

Combining Durability and High Capacity in Material Handling

Mechanical VRCs, known for their durability and high capacity, are a reliable material handling solution. Designed for endurance, these VRCs can handle substantial loads, making them ideal for demanding environments.

With the ability to move materials vertically swiftly and safely, mechanical VRCs significantly reduce manual labor hours and minimize the risk of accidents, leading to fewer delays and greater productivity.

Mechanical VRC Families

Within the Mechanical VRC family, there are multiple designs to meet your application’s requirements. Each VRC can be customized and built to your specifications, ensuring optimal performance and results.

Maintenance Ensuring Safety and Compliance with Hydraulic VRCs

Regular maintenance and inspections ensure the longevity of your Mechanical VRC. When properly maintained, you’ll see less downtime and fewer service calls, preventing disruptions to your production and profits.

Proper maintenance also ensures safety, which is a priority when moving heavy loads between floors. In addition to meeting all safety standards, Autoquip offers custom options to provide further protection, including photo eyes, limit switches, velocity fuses, safety guards and handrails, and audible and visual alarms.

Each Autoquip VRC has a preventative maintenance schedule and checklist to protect your team and investment.

Autoquip VRC Product Family

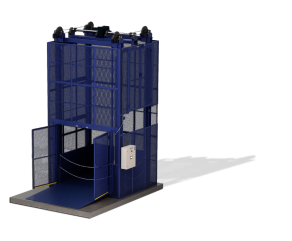

Mechanical Cantilever

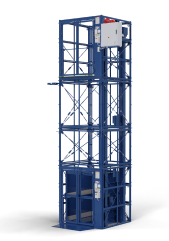

Mechanical Straddle

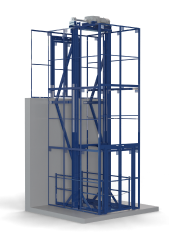

Mechanical 4 Post

Design Type

Carriage is mounted in front of guide beams.

Load pattern is straight through “Z” or on/off the same side “C” or “90 degree” over any of the 3 sides.

Low to mid-range capacity

Carriage is centered between 2 guide beams.

Load pattern is straight through “Z” or on/off the same side “C”.

Low to mid-range capacity

Carriage is mounted within four guide beams.

Load pattern is straight through “Z” or on/off the same side “C” or “90 degree” over any of the 4 sides.

Mid to high-range capacity

Actuation Type

Mechanical

Mechanical

Carriage Size

Up to 8′ W x 8′ L

Up to 10′ W x 12′ L

Up to 12′ W x 15′ L

Configuration

2-Post Cantilever

2-Post Straddle

4-Post

Capacity (lbs)

Up to 6,000

Up to 6,000

Up to 20,000

Vertical Travel

Up to 100 ft.

Up to 100 ft.

Up to 100 ft.

Levels

Multi

Multi

Multi

Standard Speed (FPM)

30 FPM

30 FPM

25 FPM

Find the Ideal Mechanical VRC for Your Business

Browse our buying guide to determine which Mechanical VRC best meets your application’s industrial requirements. Once you’ve determined the ideal Mechanical VRC, learn how we can further engineer a lift to meet your needs with our custom solutions.

Project Experience

Autoquip specializes in designing automated lift systems to meet your specific application and its requirements. Learn how we’ve helped customers streamline their operations with our Automated VRCs.

Connect with a Lift Expert

Ready to get started? Speak with our experts to receive a free quote today.

Get a Quote