High Capacity Scissor Lift Used for Glass Manufacturing

Introduction

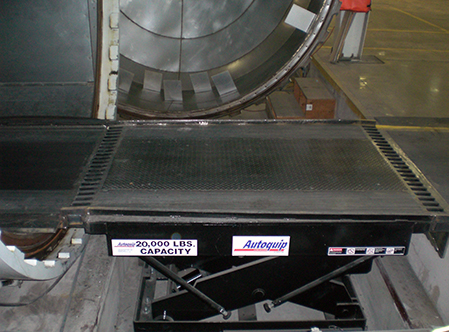

Super Titan scissor lift used for rolling loading cart over to transfer materials to furnace.

Project Challenge

Customer required a solution to transfer glass materials from a rolling cart positioned on a dock into their furnace conclaves and needed to do this by bridging a 73″ gap. The lift would need to be lowered and raised as the door opened from the furnace. The materials required a smooth transfer with a secure setting while the whole transfer process takes place.

Our Solution

Autoquip designed and built the Super Titan to include several options to meet all the customer requirements. The lift was equipped with expansion joint fingers along each edge of the lift and matting fingers to be shipped loose for attaching to dock and conclave area. Autoquip also designed hydraulic actuated support legs wired with lift up and down (2) limit switches to activate indicator lights showing legs up and legs down. Support legs will support platform at operating height of 41″. The platform also has angled wheel curbs along each side, so the cart cannot roll off the sides of the lift. The platform also has smooth sides along the side of the platform and 4-way non-skid surface for grip when pushing the cart in and out of the conclave.

The Results

The Super Titan provided a flexible solution for incorporating into their existing process. It allowed for continuous operations in a non-stop production environment meeting the demands of their customers.