Basket Tilters Save Reach

Introduction

Ergonomic basket tilter decreases work-related back injuries and improves productivity for parts assembly process.

Project Challenge

A manufacturer wanted to reduce employee exposure to lower back injury due to excessive bending and reaching during the manual material handling tasks associated with a manual assembly process. Employees had to reach into baskets of small parts during assembly, and as the basket emptied, employees were forced to reach further down to retrieve the parts – typically with knees locked and using only their lower back for lifting strength. They required a solution to incrementally adjust the degree of tilt of a work platform to ergonomically “fit” a wide variety of employee heights and reaches, which would dramatically reduce bending and reaching motions associated with component part retrieval during the assembly process.

Our Solution

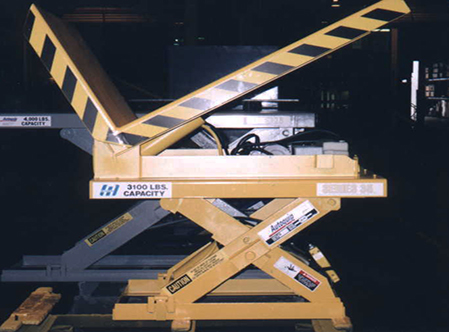

In this fairly straightforward ergonomic application, Autoquip recommended a solution in which a hydraulic tilter was mounted to the floor with the basket placed on the tilter platform. The tilter provides a wide range of adjustability and operator control of the baskets being positioned for part retrieval. Foot-operated controls allow the operator “hands-free” control of the material handling equipment as he/she performs assembly tasks.

Fork trucks deliver and pick up baskets of various sizes to and from this workstation tilter – depending on the assembly being built at the time. Operators then control the angular position of the load, depending on the basket style and component part size/orientation. A tilter “lip” at the front of the tilter platform was sized according to customer requirements (determined by basket style and height) to provide load stability during the tilting process.

Specifications for this Tilter Application:

Platform Size: 42″ x 42″

Tilter Capacity: 5,000 lbs.

Degrees of Tilt: 45 degrees

Actuation: Hydraulic

The Results

Through the addition of this basket tilter, manual material handling tasks associated with retrieving parts from bins and baskets is now more ergonomic, reducing employee exposure to lower back injury and increasing work station efficiency.