Lift Equipment Safety In The Workplace In 2022

For over 70 years, Autoquip has designed and constructed lift equipment with a primary focus on maintaining the safety of people, products, and machines. In recent years, as manufacturing processes and applications have become more integrated and complex, businesses across the supply chain are expecting more from their equipment which brings on a whole new level of safety considerations. Autoquip continues to lead the way in developing new and innovative solutions that result in safer work environments for our customers.

A Safer System with IOT Enable Lift Equipment

IoT, or the Internet of Things, is becoming the operational standard for factories looking to increase safety, reduce costs, and streamline operations via connectivity. IoT leverages the internet to connect devices with equipment, so they work together to provide insight and data to the operation. Gone are the days of self-contained units that worked discreetly. Today’s manufacturing equipment is designed with sophisticated controls and sensors that collect, exchange, and analyze data. This level of communication and information being relayed from the equipment enables companies to anticipate and address possible safety risks and prevent potential issues before they impact workers.

Autoquip offers AQ Connect for cloud-based monitoring for IOT enabled lift equipment. AQ Connect monitors operations, tracks cycles in use, equipment status and performance, and can provide preventative maintenance reminders that help you ensure a safe operation. When the system generates an alert, the operator receives an on-screen notification. Alerts can also be routed to remote locations and smartphones. A timely response to alerts can prevent component damage and reduce maintenance costs. AQ Connect ensures that your teams stay informed and can respond to issues quickly.

Identifying Potential Safety Risks

Our Autoquip teams work to understand each customer’s unique operational model and safety requirements. We review each application requirement to determine the potential risks. We ask specific questions to determine how and where the lift will be used and what human interaction may be needed.

The most common safety concern impacting the use of lift equipment is employee awareness. Frequently, employees are working near the lift, but not with the lift itself. We take all this into account when we design your lift and recommend intelligent control systems that can help you monitor these types of potential safety risks.

Intelligent Control Systems Increase Safety & Reduce Maintenance Costs

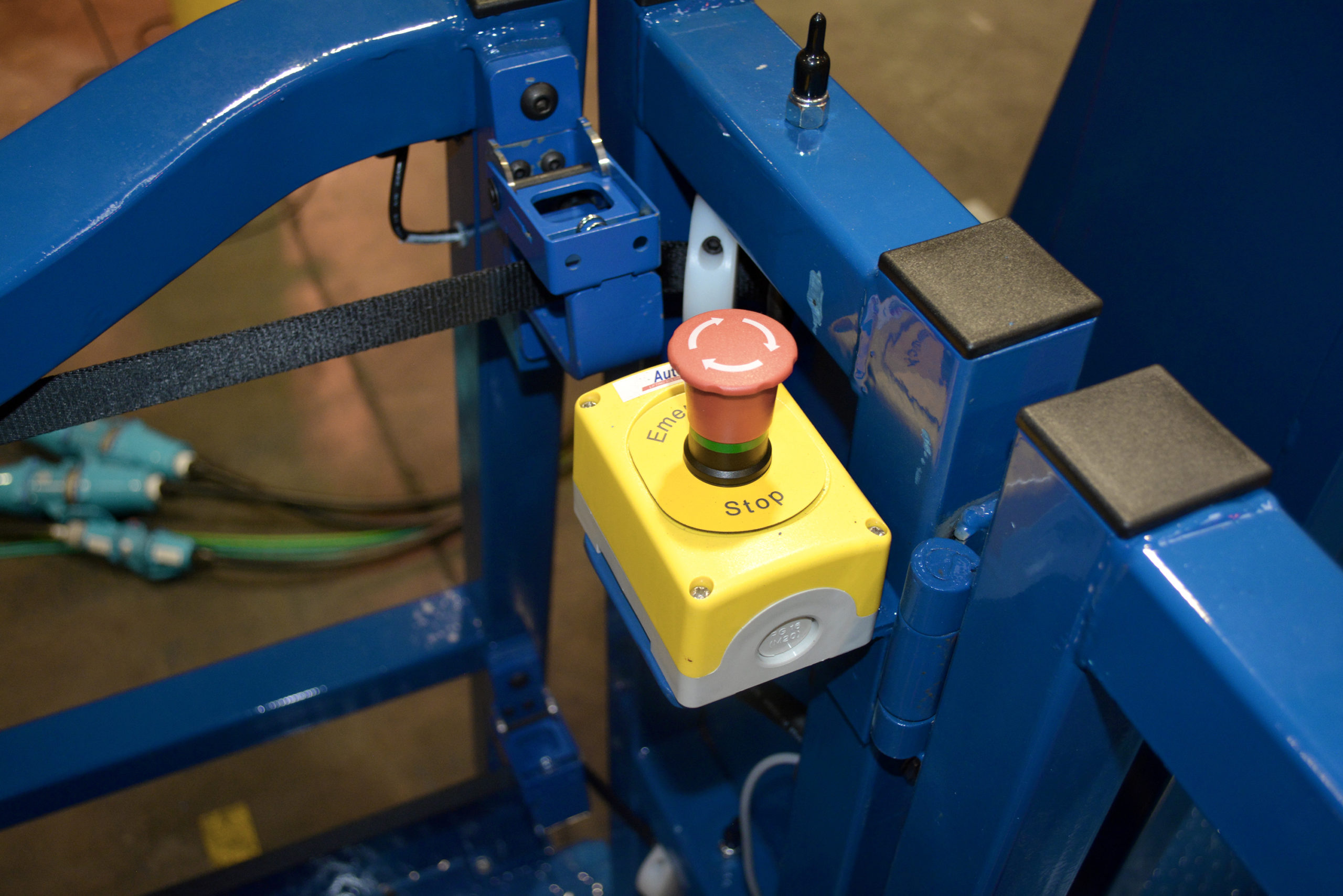

Intelligent controls can be added to monitor and send alert notifications, when your application requires more than the standard safeguards such as handrails, enclosures, or accordion skirting. These control panels can be configured and programmed to detect the presence of a worker near a moving platform and stop the lift in action. Autoquip can install a variety of safety features and advanced control options that address your specific safety requirements.

How Safe Is Your Environment?

Do you need to improve safety and efficiency in your workplace? Our teams can partner with you to develop an integration and controls strategy that makes sense for your business. We have extensive experience working with dozens of industries and applications. Don’t take a chance when it comes to safety! Contact us today for a free quote!