Multi-Lift System Integrates with Paper Unwinding Equipment

Introduction

(2) Tork Lifts and a Compact Lift for paper roll unwind/wind system designed to maximize productivity.

Project Challenge

New Era Converting Machinery Inc. provider of custom designed equipment solutions for the web handling industry wanted to provide their customer with a complete turnkey system for their paper rolling process.

They have purchased lifting equipment from us before and knew we had the expertise to engineer a solution to meet their unwinds and winder positioning needs.

Our Solution

The application for the paper roll processing includes a multiple lifts for a fully integrated system:

Lift 1 (TRK-048-0060-T1) is labeled as a carrier unwind which supports paper rolls coming from an unwinder machine.

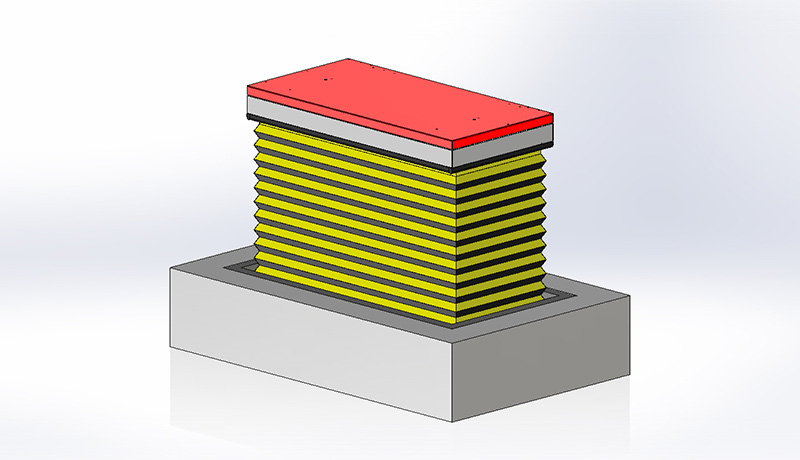

This lift is pit mounted and lowers to be flush with the floor for ease of loading and unloading product. While being in the raised position the lift can accommodate the material offloading from the machine. Due to the alignment migration, the lift was supplied with a spring loaded to return the platform to a home position. The forward and back shuttle operation of the platform allows for a full 8” of adjustment with 4” in each direction. The platform was also predrilled for customer installation of a fixture.

Lift 2 (TRK-048-0060-T1) is labeled as a carrier winder which supports paper rolls being loaded onto the machine for processing.

This lift is pit mounted and lowers to be flush with the floor for ease of loading and unloading product. While being in the raised position the lift can accommodate the material loading onto the machine. To assist in the alignment for loading this lift also has a powered shuttle of 10” and must be retracted to a home position for the lift to be fully retracted into the pit. Like the unwinder, the platform was also predrilled for customer installation of a fixture. For added safety the platform perimeter includes a safety sensing edge that disables the lift operations should this sensing edge make contact with something.

Lift 3 (CPT-036-0060-SF) is labeled as a product winder for positioning the product to be loaded on a winding machine.

This lift is surface mounted with lift and powered tilt feature. The tilting platform includes a pressure switch to sense the material is in position on the platform. A “U” shaped lift platform outlines the tilting platform and is setup to be manually pulled out to act as a bridge for the material. This manual pullout shuttle section also includes a sensing edge allowing the lift to be operated while extended should the sensing edge make contact with anything. This will disable the lift operation until he area is cleared to resume operations.

AQ Project#

156007 & 158703

The Results

Having worked with us before, New Era Machinery had confidence that our team would provide a tailored made lift system for their customer’s unwinding applications. Autoquip is committed to providing solutions that maximize productivity and make processes simpler.