Applications

Automation

Autoquip specializes in designing automated lift systems for manufacturing and warehouse automation. Our lifts are easily integrated into new or existing systems. Our control engineers have the knowledge and experience to integrate a variety of programming to support most automation requirements from conveyors to machine fed applications.

Experience & Expertise

Lifting and handling solutions Autoquip designed and manufactured for automation applications include:

Automated conveyor and lift system to move resin mixers through mixing process. Freight lifts are controlled by an Allen-Bradley PLC with soft start/stop controls.

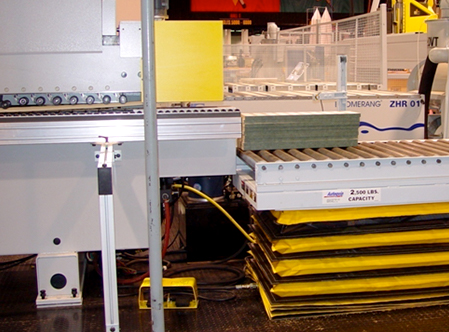

Standard hydraulic scissor lifts are programmed to automatically adjust to working height for stacking applications. Indexing technology uses photoelectric sensors to signal lifts for operation.

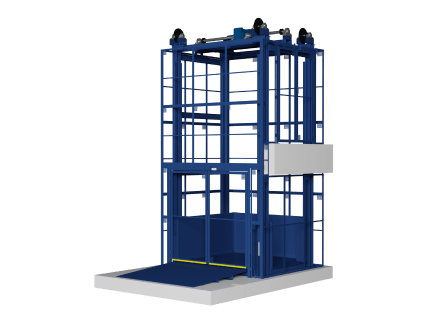

High Cycle Freightlift integrates with repetitive conveyor systems and is programmed with fully automated controls, requiring no operator interface.

Two (2) synchronized platform sections are programmed to operate with HMI controls, synchronizing both sections together or operating only one.

Work platform lift positioned along a traversing base uses advanced control programming to move lifts in and out of the automated welding process.