Applications

Bin & Basket

For over 70 years, Autoquip has been a world-class provider of equipment solutions for performing safe and efficient bin and basket handling applications. We design and manufacture a wide range of industrial lift and tilt products that tilt and raise the top layer within a worker's unique ergonomic "power zone."

Experience & Expertise

Lifting and handling solutions Autoquip designed and manufactured for bin and basket applications include:

Pneumatically controlled hydraulic non-intrusive tilters are floor mounted and have ball transfers on the deck surface to receive conveyed bins of parts onto the tilter. The bin is tilted, but due to non-intrusive design, does not tilt into the worker's limited floor space.

Standalone 45-degree industrial tilters angle baskets, boxes, and other containers to ergonomic work heights, minimizing bending and reaching by employees as they scoop out ingredients.

DC-powered portable high-hinge hydraulic tilter tilts lumber scraps on end into bins or baskets for easier clean up.

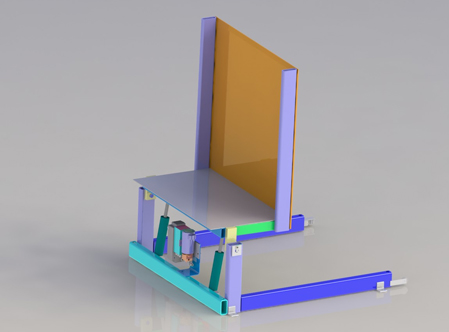

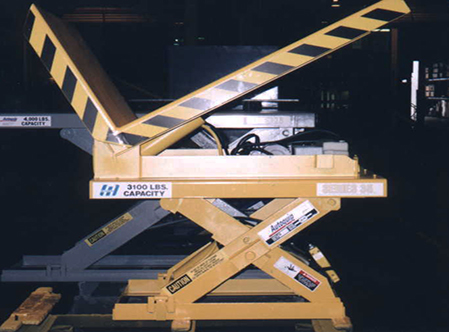

A 45-degree tilter is mounted on top of a scissor lift, allowing a fork truck to place bins or baskets of small metal castings on top. Then, the parts are tilted up to an operator during an assembly operation. Lift and tilt motions can be controlled separately.

An integrated lift and tilt design. As the scissor mechanism opens away from the operator and raises the load, a set of tilting arms simultaneously tilts the load towards the operator. This creates an overall lift and tilt motion that is non-intrusive to the employee.