Double Pantograph Scissor Lift Integrates with Assembly Line

Introduction

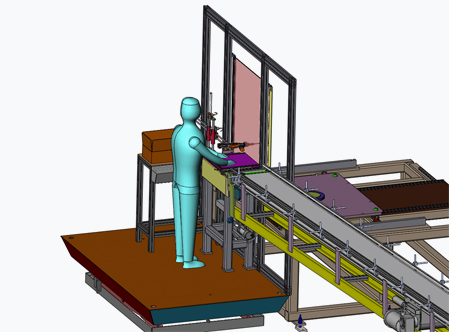

Double Pantograph scissor lift used to position workers to tooling for automated assembly process.

Project Challenge

Calvary Automation Systems manufacturer of turnkey automated equipment for a variety of industries including health care, automotive, consumer and office products needed to keep their assembly line running at an optimal pace. Workers in their assembly line needed to be able to move to multiple locations quickly to position for the installation of screws and wiring.

Our Solution

The customer specified the travel height of 84″ and a larger platform for worker access. The lift also had to lower and raise the worker to multiple locations for wiring and installing screws on a special piece of tooling. Autoquip’s Double Pantograph was the clear choice. The power and durability of the lift and the precise positioning of the controls allows for the lift to egress up and down moving the worker along making the connections. Specs: 84″ Vertical Travel, 60X96 Platform, Internal 5HP power unit wired to 460VAC 3PH 60HZ

The Results

Autoquip’s quick response to understand the customer’s needs, and providing a cost effective lifting solution helped Calvary move their assembly process along to achieve a successful product delivery date to their end customer.