Ladle Lift for Steel Refractory Process

Introduction

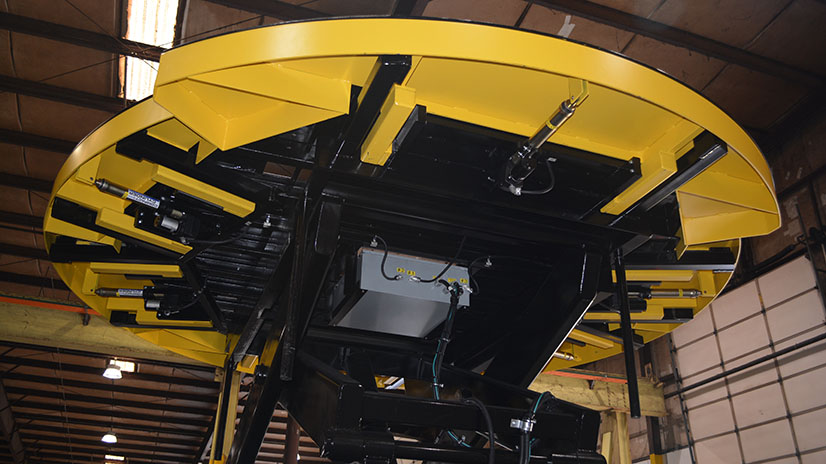

Custom designed ladle lift with retractable shuttle decks takes workers closer to inner ladle wall to help replace firebrick.

Project Challenge

A stainless-steel foundry in Calvert, Alabama needed to re-line their steel casting ladles due to refractory degrades. The wanted a work platform lift solution that could be used as a “man lift” to make it easier for workers to access the inner wall of these large ladles to rebrick them.

Our Solution

Solution:

Our team of engineers designed a work platform lift with a “fish” shaped platform that has multiple shuttle decks to enlarge the platform area to match the inner wall shape and height of the ladle. It has a high-capacity load bearing center area and is designed to be lifted in and out by an overhead crane.

Controls Operation:

Our controls engineers designed the operating system to power the lift, move the lift up/down and retract/detract the shuttle decks. They integrated a wireless pushbutton control which is paired to the receiver so that you can have several systems in the same area without any crosstalk between one system to another. The wireless pushbutton option allows for greater flexibility in the sense that the operator can control the machine from virtually any position.

AQ Project#

155080

The Results

The main advantage of Autoquip’s ladle lift is the safety to the operator who now has a safe and efficient method for replacing the brick. Productivity is increased by allowing the workers closer access to the inner walls which reduces replacement time significantly