90 Degree Upender “Flips” Large Aerospace Parts

Introduction

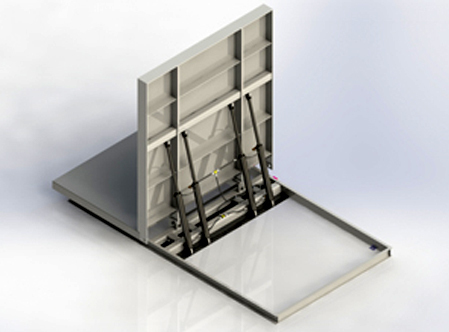

Autoquip’s 90 Degree Upender integrates with other aerospace tooling systems to upright large, complex aerospace parts.

Project Challenge

Global Tooling Systems a designer and integrator of tooling systems for the aerospace industry has been working with MRA Systems Inc., a division of GE to find a lifting solution that will upright finished machined parts to prepare for palletizing and transport. MRA Systems has been using slings and overhead cranes to move the parts which have become an arduous and complex task.

Our Solution

Autoquip was asked by Global Tooling to provide a recommendation to resolve the load transfer issues presented by MRA System. Autoquip recommended the 90 Degree Upender “flip-flop” to optimize the assembly process. The flip-flop is capable of repositioning heavy loads and controlling the load as it flips and descends onto pallets. For this particular application, Autoquip custom fit the platform with a 1-inch lip around base of platform to assist assembly workers in properly placing the materials. Autoquip was chosen to supply the lift equipment because of our history of providing quality lifting solutions to several other GE divisions. In addition, we were able to meet the customer’s aggressive lead time for approval drawings and quick shipment of the equipment.

The Results

- Past successes with other GE divisions gained customer’s confidence.

- Autoquip’s technical knowledge base determined the ideal lifting solution for a complex application.

- Customer’s demand for early product delivery realized by Autoquip’s accelerated production time.

- Quality and reliable lifting product equals quality assurance and safety for assembly workers.