Extra Narrow Scissor Lift Integrates into Automated System for Handling Gas Pipes

Introduction

Extra Narrow Scissor Lifts are used to transfer gas pipes as part of a completely automated system.

Project Challenge

A machine integrator and manufacturer of handling systems for gas line utility companies were looking for a lifting solution to integrate with an automated system for handling gas pipe. The gas pipe handling system is built to handle gas pipes that are lightweight, large in diameter, long-length, and formed welded. The lift equipment will be used to transfer the pipes to a different part of the automated system.

Our Solution

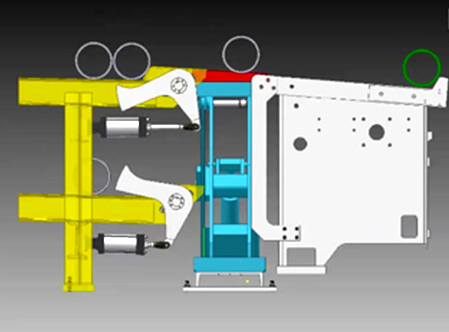

Autoquip furnished (3) extra narrow Series 35 Scissor lifts each with 2500 lb. capacity – 36″ of travel, and a 16″ wide x 48″ long- smooth steel platform. The integrator furnished the sloped platform tops mounted onto the Scissor lifts. The lifts are synchronized in either a two or three lift combination based on the overall pipe lengths produced. The integrator provided their own power unit utilizing Allen Bradley PLC controls for synchronizing. The Extra Narrow lifts were chosen due to narrow space constraints and the raising and lowering speed of 7 seconds.

The automated system operates in this sequence:

A gravity handling system with a mechanical gate releases a pipe onto the lift platform.

The lift then raises to an elevation of 27″ and the sloped platform discharges the pipe onto the fixed height stand for further processing.

The Results

Autoquip’s Extra Narrow Scissor Lifts helped complete the automated system for the customer enabling them to meet their production objectives.