Hydraulic

Elevating Efficiency withVertical Reciprocating Conveyor Solutions

Vertical Reciprocating Conveyors, commonly referred to as VRCs, are the ideal lifting solution for safely moving cargo, equipment, or supplies from one level to another. As the distinguished leader in lifting technology, we offer industry-leading experience designing and building custom VRCs that enhance safety and efficiency while transporting cargo vertically.

Use our VRC Application Form tool to design a VRC to your exact need.

VRC AdvantagesCost-Effective, Versatile, and Safe

- Ensure reliable movement of high-capacity freight between multiple levels

- Optimizes space, decreasing the footprint in your facility

- Provides greater functionality and safer operation than forklifts

- Generates a quick return on your investment

- Creates a safer work environment by meeting or exceeding ASME B20.1 safety requirements

- Enables quick and efficient transfer of product to mezzanine level

- Accommodates precision positioning requirements

- Handles heavy-duty applications

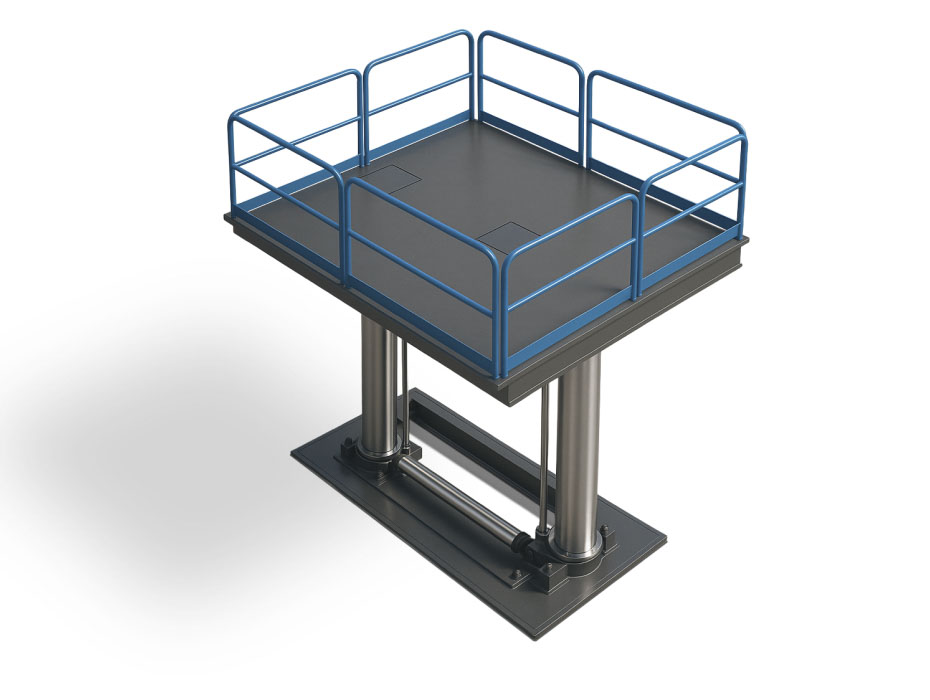

VRC TypesMechanical and Hydraulic Solutions

There are two primary types of VRCs (also known as Vertical Lifts, Freight Lifts, and Material Lifts) available: Mechanical and Hydraulic. Additionally, VRCs can further be broken down into Straddle, Cantilever, 4 Post, and Freightlite models each manufactured for a specific purpose. Each type delivers unique features and benefits, so understanding the differences is essential to finding the right solution.

We will work closely with you to fully understand your unique needs and determine the best VRC type to accommodate your space and lifting requirements.

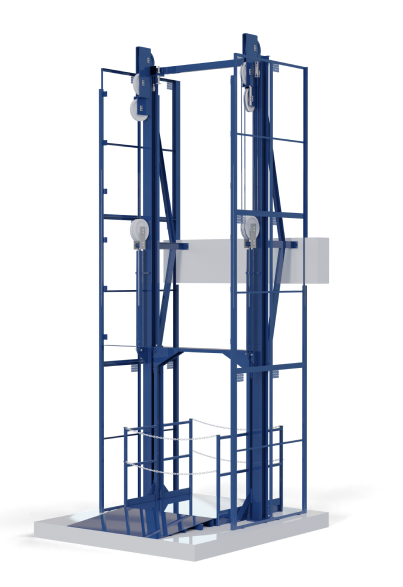

Straddle

Straddle lifts are designed to handle the movement and transfer of larger loads by “straddling” the carriage between two beams. The straddle model provides a stable platform but offers fewer loading options. Our standard models can travel up to 30 feet.

Available in both mechanical and hydraulic configurations.

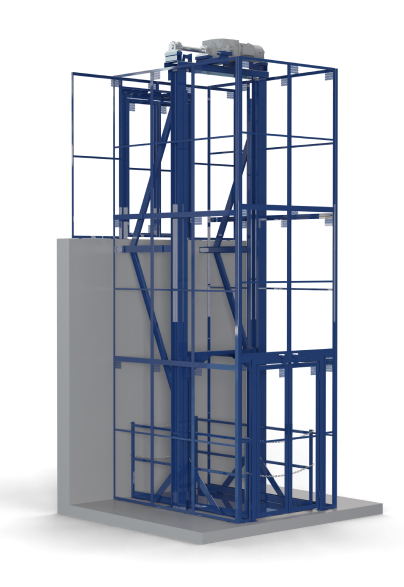

Cantilever

This 2-post lift design eliminates overhead restrictions by using a cantilevered carriage off the guide beams. Standard models can handle loads up to 6,000 pounds and travel 12 feet. We can extend the travel distance using custom engineering if needed.

Available in both mechanical and hydraulic configurations.

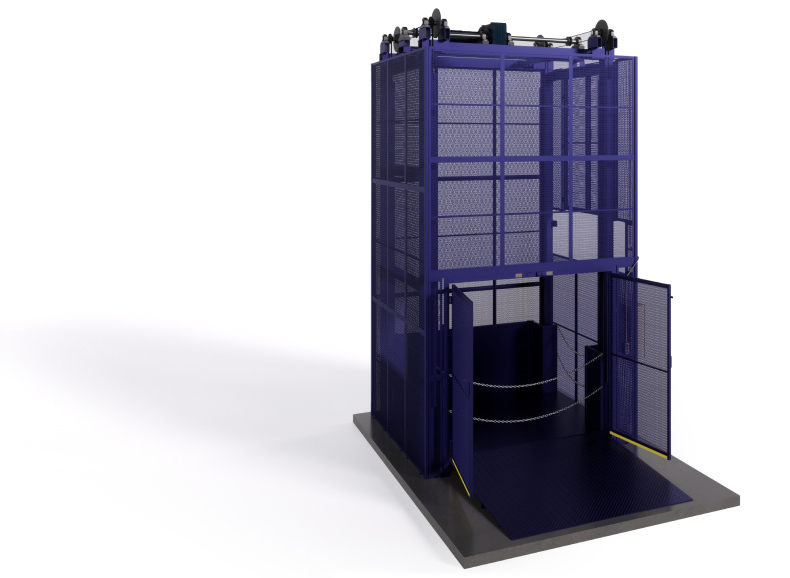

4 Post

Lifts using this design draw support from each corner. 4 Post lifts offer maximum versatility and are more costly, but they provide the most capacity, precision, vertical travel, deflection, and loading options.

Due to the features of the 4 Post design, it is available in a mechanical version only.

Freightlite

This material handling lift is ideal for moving lightweight loads below 3,000 pounds. Freightlite lifts can travel up to 15 feet. The reinforced platform minimizes deflection while maximizing stability.

These hydraulic only units are cost-effective and easy to install.

VRC Product Selector GuideChoose the Right VRC for Your Business

There are countless applications for VRCs to transport materials, supplies, and equipment from one level to another. Our Product Selector Guide presents the most common VRC configurations to help you understand which is best of your lift application.

Autoquip VRC Product Family

Hydraulic Cantilever

Hydraulic Straddle

Hydraulic Freight Lift

Mechanical Cantilever

Mechanical Straddle

Mechanical 4 Post

Package Lift

Design Type

Carriage is mounted in front of guide beams.

Load pattern is straight through “Z” or on/off the same side “C” or “90 degree” over any of the 3 sides.

Low to mid-range capacity

Carriage is centered between 2 guide beams.

Load pattern is straight through “Z” or on/off the same side “C”.

Low to mid-range capacity

Carriage is mounted in front of guide beams.

Load pattern is straight through “Z” or on/off the same side “C” or “90 degree” over any of the 3 sides.

Low capacity

Carriage is mounted in front of guide beams.

Load pattern is straight through “Z” or on/off the same side “C” or “90 degree” over any of the 3 sides.

Low to mid-range capacity

Carriage is centered between 2 guide beams.

Load pattern is straight through “Z” or on/off the same side “C”.

Low to mid-range capacity

Carriage is mounted within four guide beams.

Load pattern is straight through “Z” or on/off the same side “C” or “90 degree” over any of the 4 sides.

Mid to high-range capacity

Variety of Configurations

Low Capacity

Actuation Type

Hydraulic

Hydraulic

Mechanical

Mechanical

Mechanical

Mechanical

Carriage Size

Up to 8′ W x 8′ L

Up to 8′ W x 12′ L

Up to 6′ W x 6′ L

Up to 8′ W x 8′ L

Up to 10′ W x 12′ L

Up to 12′ W x 15′ L

Up to 4.5′ W x 4.5′ L

Configuration

2-Post Cantilever

2-Post Straddle

2-Post

2-Post Cantilever

2-Post Straddle

4-Post

2-Post

Capacity (lbs)

Up to 6,000

Up to 6,000

Up to 3,000

Up to 6,000

Up to 6,000

Up to 20,000

Up to 500

Vertical Travel

Up to 30 ft.

Up to 30 ft.

Up to 15 ft.

Up to 100 ft.

Up to 100 ft.

Up to 100 ft.

Up to 25 ft.

Levels

2 Levels

2 Levels

2 Levels

Multi

Multi

Multi

Multi

Standard Speed (FPM)

25 FPM

25 FPM

15 FPM

30 FPM

30 FPM

25 FPM

30 FPM

Factors to Consider When Selecting a VRC

A VRC is a versatile piece of equipment, but it’s critical to ensure the lift you choose is a fit – regarding both your application’s requirements and the space available in your facility. When choosing a VRC, consider the following factors.

- How high will your VRC need to travel?

- What’s the weight of your max load?

- What size cargo will the lift need to accommodate?

- What’s the loading pattern?

- Where in your facility will the lift be installed?

- How frequently will the VRC be utilized?

- Do you require custom features?

- Is a special speed required?

Our Custom Vertical Reciprocating Conveyors solve even the most challenging high-reach storage needs.

Watch to Learn More

Autoquip Advantage The Leader in Custom VRCs

After 75+ years of experience, we know that one size does not fit all when it comes to industrial lifts. Our highly skilled team of engineers and technical experts maintain a reputation for taking on diverse specialized projects and delivering exceptional results. That’s why our industry-leading design and fabrication services are able to deliver the best solution for any application.

Expect More With Autoquip VRCs

- Streamlined operations with an intelligent control panel system

- Seamless integration with conveyor systems, AGVs, and robotics

- Custom options to improve functionality for your unique application

- A team with extensive background in advanced engineering capabilities

- Design tools like our in-depth VRC Application Form

- Access to the industry’s largest design library

Use our VRC Application Form tool to design a VRC to your exact need.

Automation Solutions Automated and Integrated VRC Systems

Autoquip leads the lifting industry with advanced automation capabilities that enhance the efficiency, safety, and flexibility of your VRC. By integrating state-of-the-art automation technology, our VRCs seamlessly automate material handling processes, reduce manual intervention, boost productivity, and foster a safer, more efficient work environment.

In collaboration with OSCO Controls, our division of highly skilled controls engineers, we deliver bespoke automation solutions tailored to your needs. Our expertise in control system design, PLC programming, and systems integration ensures reliable and efficient automated material handling tackling the most challenging equipment automation problems.

Autoquip is setting a new industry standard with the introduction of VRC AutoLock – AMR Restraint.

Offering Comprehensive Automation Capabilities

- Customizable and adaptable automation capabilities for any industry

- Controls with Remote Monitoring & Diagnostics Capabilities

- Interconnected Systems for Streamlined Operations

- Meet and Exceed Safety and Compliance Standards

Custom Solutions Solving Complex Problems with Custom VRCs

When your application demands more than standard VRC offerings, our highly skilled team of engineers and technical experts implement custom design solutions to solve your unique challenges. We’re proud to maintain a reputation for taking on specialized projects and delivering exceptional results.

Whether you need a lift that is automated, high-cycle, or integrated with other factory equipment, our highly skilled design and engineering team can deliver. With our ability to manufacture the industry’s most innovative custom lifts, we can meet any future challenge, keeping your business state-of-the-art.

Project Experience

Autoquip specializes in designing automated lift systems to meet your specific application and its requirements. Learn how we’ve helped customers streamline their operations with our Automated VRCs.

ASME B20.1 Safety Standards

Safety is the first priority when moving heavy loads between floors. Autoquip VRCs improve results while protecting employees from potential injury. All of our VRCs & freight lifts meet or exceed the safety standards of ASME B20.1 (Safety Requirements for Conveyors and Related Equipment), which applies to material lifts not designed or intended for riders.

Additional VRC Resources

VRC Training Courses

Autoquip offers proprietary training for team members, dealers, and other partners for general knowledge, installation, maintenance, and troubleshooting.

Autoquip University offers courses specifically prepared to help your team excel in any position while using your Autoquip VRC.

Contact your Autoquip representative or visit our Autoquip University to learn about VRC installations and more.

Maintaining Your VRC

A VRC is designed to simplify workflows and increase efficiency. Maintenance is essential to prevent downtime and keep your lift operating at peak levels.

General and routine maintenance schedules are outlined in each VRC manual, but Autoquip simplifies the process by offering a Planned Maintenance Program using qualified and experienced personnel.

Frequently Asked Questions

Both passenger elevators and cargo lifts can carry riders, but with different purposes.

With a passenger elevator, the rider is the focus of the transportation. These elevators have different safety standards and frequently have appealing interiors and finishes.

A cargo lift is a type of freight elevator that allows people to transport heavy loads to various levels of a building. While the VRC won’t work, Autoquip has a variety of lifts that can carry both cargo and rider safely to their destination.

As the name implies, a passenger elevator is intended to transport people through a building, while a freight elevator carries goods and materials. A VRC is a type of freight elevator specifically designed for carrying cargo rather than passengers.

Material handling is a fast-paced and ever-evolving function. With advancements in technology, changes in consumer behavior, and a shifting job market, the ability to adjust and acclimate will remain a constant for anyone in this line of business.

VRCs are versatile and adaptive, making them a sound investment for material handlers. They’re manufactured to be durable and long-lasting. Their agility allows your team to maximize floor and overhead space as you grow, making room for more inventory and increased revenue.

VRCs are an ideal lifting solution for safely moving cargo, equipment, or supplies from one level to another.

Autoquip VRCs are known for their consistent performance, durability, and small footprint, making them the lift of choice for industrial buildings in need of an economical solution to increase production and improve customer service.

Autoquip has been the leader in lifting technology for 75+ years, proudly manufacturing custom solutions in the heartland of America. We leverage this experience to meet exact specifications, improving material lift and storage for industrial mezzanines, retail stores, restaurants, warehouses, conveyor systems, and more.

Using our proprietary design process, Autoquip assesses dozens of factors to ensure each VRC is ideally designed for the specific facility and application where it will be utilized. We strike the ideal balance between weight capacity and versatility by considering load weight, travel distance, necessary integrations, and more factors.

We provide a smooth and efficient installation process utilizing a network of professional installers. This network consists of experienced and certified technicians who specialize in VRC installations.

Explore More Autoquip Solutions

Get In Touch With Our Experts

Ready to improve your workflow? Contact our team to start your project or request a quote today.

Get A Quote